A Booming Market Is Inspiring Innovation for 3D Printing in Dental.

3D printing in dental is getting more popular by the day. In 2020, the market is now worth $2.7 billion and this figure is expected to rise to $9.7 billion by 2025.

It’s no wonder why 3D printing has enjoyed so much success in the dental industry.

3D printing models enable a more efficient workflow for dentists and dental technicians. They have multiple applications in the industry (dental implants, clear aligners, dentures, crowns and more) and result in more accurate end-results thanks to the ability to print complex designs.

These advantages are best achieved by desktop solutions, which are complete solutions that include a printer, print software, wash and cure.

Many of the companies offering desktop solutions in the dental market have experienced rapid growth in the last few years.

This is true for both additive manufacturers (the specialists in 3D printing trying to crack the dental market) and dental manufacturers (the dental experts trying to create their own 3D printing solutions).

An Interview with Formlabs

Formlabs are one of the dental success stories to come out of the additive manufacturing space. In 2011, the company started with just two graduates from MIT. Now, they have grown to a team of 650 people and have sold over 60,000 printers (30% of these in dental).

I spoke to Christof Aeugle, who’s their Sales Director of EMEA, about advances in 3D printing and what’s making their solutions stand out in the dental industry.

Sales Director Dental EMEA at Formlabs

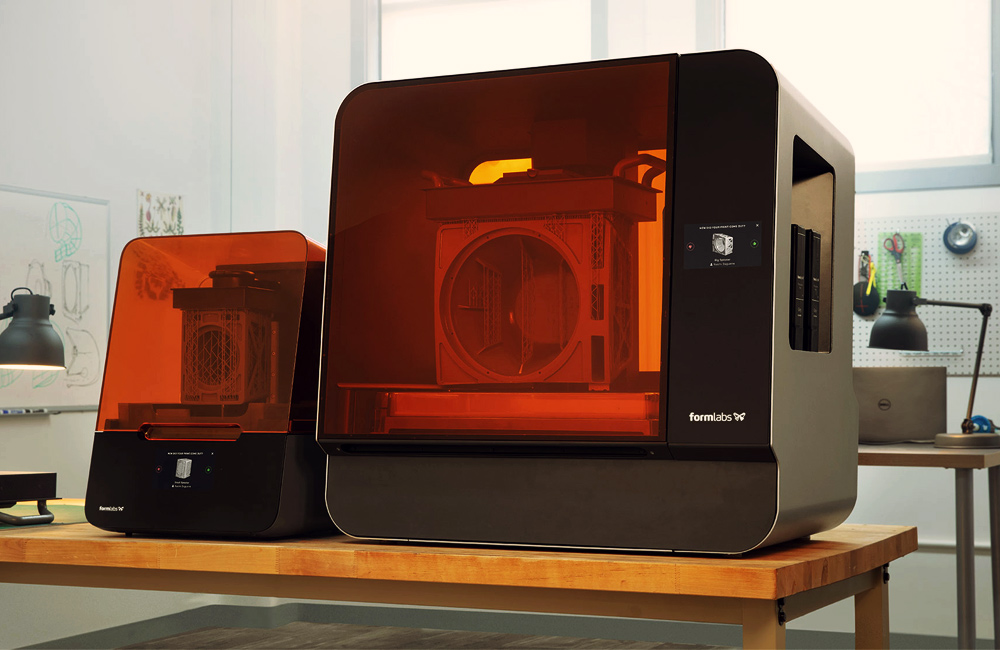

Formlabs’ offering focuses on their Form 3 B and Form 3BL printers. These printers use low force stereolithography (LFS) technology, which produces higher resolution than stereolithography (SLA) printing.

LFS and SLA printers – which make-up the Formlabs offering - are considered slower than digital light processing (DLP) printers, the other common type of 3D printer found in dental.

However, Christof explained that while DLP printers are faster, you shouldn’t only look at print time. You must also consider post-processing, curing and washing. When this is taken into account, he claimed that Formlabs’ automated solutions mean that their overall process speed is comparable.

So, when speed is no longer a deciding factor, SLA printers are the better option thanks to their higher levels of accuracy and surface quality.

If you look at our surgical guides, or even at our crowns, the surface is very glossy and the quality is better.

He also told me how strategic partnerships played an important role in the company’s growth and success. My colleague Dom Turner spoke about in his latest article with Brian Ganey, GM of Oral Health at Carbon, and Jonathan Lim, the Head of Marketing at Structo.

Formlabs have invested over $1 million in Spectra Photopolymers, their supplier of materials since 2012. Spectra are one of the main reasons that Formlabs have been able to enter the 3D printing market niches like dental. This is because their biocompatible materials comply with FDA and CE regulations.

With 3D printing desktop solutions, customer service is also very important to keep labs and practices running. That’s why every printer Formlabs sell comes with a dental service plan. If the customer has a problem with it, they’ll get an exchange printer within 48 hours.

We don't let our resellers provide the service. It is important for us to provide direct service to all our dental customers because the areas of failure are quite different to other desktop devices on the market. Our customers need our specialist advice and support.

This level of support is important because 3D printing is still relatively new to the dental space. This makes ease of use is a crucial factor too – especially with software.

Formlabs use PreForm, which is free for customers to download on both Apple and Mac.

The process starts with the dentist/technician designing the model in standard CAD software, then they import the STL or OBJ file into the print preparation software, PreForm. The model is then ready to upload to the printer in minutes for the build to start.

Formlabs are not Alone

It’s not just Formlabs that are offering fantastic desktop solutions in dental.

Structo, a Singaporean start-up, have brought to market the world’s first desktop printer that automatically prints, washes and cures. This means that their customers don’t have to buy separate hardware, saving them money and streamlining their processes.

In the US, Sprintray offer a smaller desktop solution, Moonray. This has a seamless product ecosystem and strong customer support.

On the DLP side of the market, there’s also EnvisionTec - who you’ll often find at the bleeding-edge of innovation. Their D4K Pro is the highest resolution 4K desktop 3D printer and has the fastest print speed for a standard DLP printer.

The D4K Pro is built on an industrial 4K DLP projector, which guarantees stable performance for many years. It’s compatible with all EnvisionTEC DLP resins for the dental industry, providing essential solutions for applications from models to full dentures and everything in between.

For now, this desktop solution is only available in the US.

In Europe, DWS have the XFAB 3500PD which combines precision with high throughput performances.

Equipped with advanced Nauta and Fictor software for adjusting print parameters, it is ideal for multiple applications including orthodontic arches for thermoformed aligners, dental models, biocompatible surgical guides, diagnostic and medical imaging models and more.

As you can see, 3D printing in dental is a booming market. There’s an abundance of exciting technologies coming from companies big and small, from all over the world.

3D printing is now a major part of the dental industry and its benefits are being enjoyed globally.

If you'd like to chat about this article and 3D printing technology in dental, email me at Jerome.Richards@medical-cm.com.

You can find more dental industry specific content like this on my consultant page.

Recommended.

A Booming Market Is Inspiring Innovation for 3D Printing in Dental.

3D printing in dental is a booming market. There’s an abundance of exciting technologies coming from companies big and small, from all over the world.

The Unknown Unknowns of M&A

Even if you’ve been through the process, you may not be aware of exactly what goes into M&A deals. Today, we’ve tried to look into that in a little more detail with Transaction Liability Team Leader Grant Hollis from CFC Underwriting.

The 4 Day Week

As businesses prioritise the wellbeing of their employees, the concept of working a 4 day week is shifting from distant pipedream to reality for a range of organisations around the world.

Additive & Dental Manufacturers - Room for Both in the Dental Space?

The dental market is in transition. As we move progressively toward more digital solutions, the ability to 3d print implants and other dental products and devices has become more and more important.

Comments.