Discussing 3D Printing in Dental with Two Tech Leaders.

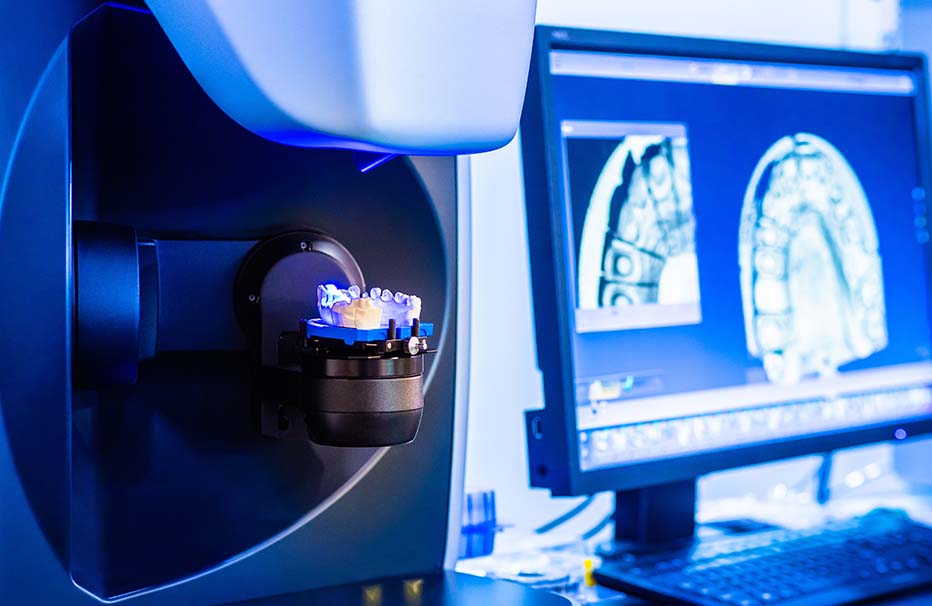

3D printing and digital models are gaining momentum in the dental industry – and it’s no surprise.

3D printing models enable a more efficient workflow for dentists and dental technicians. They have multiple applications in the industry (dental implants, clear aligners, dentures, crowns and more) and result in more accurate end-results thanks to their ability to print complex designs.

So, there’s no wonder why the 3D printing market has seen rapid growth within the dental industry. By 2023, this space is expected to be worth $5bn (from $1.7bn in 2018).

As it stands, companies in this market tend to be either additive manufacturers (the specialist in 3D printing trying to crack the dental market) or dental manufacturers (the dental experts trying to create their own 3D printing solutions).

With competition growing on either side of this market, I wanted to find out the different ways that companies are trying to stand out as leaders in this niche.

That’s why I spoke to Brian Ganey, GM of Oral Health at Carbon, and Jonathan Lim, the Head of Marketing at Structo. Both have exciting 3D printing technologies and are trying to conquer the dental market.

Partnerships Create End-to-End Workflows

Carbon is one of the biggest names in 3D printing, working across multiple industries with clients like adidas and Lamborghini. Brian told me that partnerships are at the heart of everything they do – hence their collaboration with Dentsply Sirona in the dental market.

We're not just a company manufacturing 3D printers. We provide end-to-end solutions that include workflow improvements, best-in-class materials, ongoing software and feature updates, and service and support to our customers — and that's a real differentiator for us.

Working with Dentsply Sirona, the largest manufacturer of professional dental products and technologies, has given Carbon access to a competitive marketplace and allowed them to produce a successful end-to-end workflow for their dental customers.

Together, the companies produce the Lucitone Digital Print Denture workflow and material. This system offers quality in terms of strength and aesthetics, while also offering an efficient laboratory workflow.

Let’s Talk Software

Carbon’s offering includes advanced hardware, software and optimized materials. Carbon provides their customers with over-the-air software updates every six to eight weeks. This enhances the performance of printers, prevents machine obsolesces and improves operationality and performance.

The fact that this is all built into the Carbon offering with no ‘add ons’ or unexpected costs makes them a unique 3D printing company to work with – helping them stand out in the marketplace.

Making it Easy for Dentists

Combined solutions are important for adoption of products in this market, but equally are their ease-of-use. This is something that Structo pride themselves on.

Even clinicians in chairside dentistry with limited experience of CAD software can use their Velox, which allows the clinicians more time with their patients. Cutting down on time spent post-processing.

Designing products for chairside dentistry where some dentists are not that well versed with CAD/CAM technology, it’s so important to keep ease-of-use in mind.

On top of this, it has a small footprint and is easy to fit in the clinic where countertop real estate is always at a premium. It also works quickly and is the world’s first desktop printer to automatically print, wash and cure dental appliances. This is all highly beneficial for chairside use.

Making a Big Difference

At the other end of the dental market, large manufacturers face a different set of challenges in manufacturing thousands of unique dental parts per day.

At that scale, operating regular 3D printers require lots of manpower which inflates costs and makes the end-product susceptible to human error.

To solve those problems, Structo have established a dedicated product team that develops custom factory solutions incorporating various automation elements to streamline round-the-clock manufacturing at scale.

This custom factory solution is based on Structo’s proprietary Mask Stereolithography (MSLA)-powered high throughput 3D printers and involves elements like automated printing, washing and curing, resin recovery systems, quality control stations as well as application-specific elements such as automated thermoforming, trimming and laser marking for clear aligner manufacturing.

There’s No One Size Fits All Solution

There’s a common theme between the offerings that I’ve talked about so far: they’re adaptable. That’s because there’s no one size fits all solution to 3D printing in dentistry.

Jonathan explained how solutions must be provided on a case by case basis, with application-based product development the key to meaningfully solving real industrial problems.

We don't believe that there is a one size fits all solution that can be deployed to the market, despite the perception that 3D printers (or more accurately, additive manufacturing equipment) can theoretically print anything one can think of. Most industry problems require their own tailored solution to meaningfully solve a problem.

Customer Service Is Everything

It’s for this reason that both Jonathan and Brian place a strong emphasis on customer service. It’s why their companies offer training, education and support to ensure customers have exactly what they need to achieve their own unique goals.

This market remains focused in the US, but the space is growing and further global expansion only a matter of time. I’m excited to see the next steps that companies take to make 3D printing easier and more accessible for clinicians, while adding to their solutions to provide an all-in-one offering.

As the technology advances, offerings expand and the market enters new areas; patients are sure to reap the rewards.

Recommended.

Does Anyone Discuss Gender Diversity in the Dental Industry?

As social demand for increased corporate effort towards gender diversity builds, how is the dental industry taking action? Click to find out.

A Bright Future for The Dental Equipment Sector.

How can you lead in the dental equipment market, and what does the future look like for the sector? I looked to a few key market leaders to try and find out.

What Impacts Dental Implant Success?

In a crowded market, it is vital for dental manufacturers to what makes a good implant and how they can achieve this. So, what should you do next? Click to read more.

.jpg)

5 Emerging Technology Trends That Will Shape the Future of Dentistry.

From SMART toothbrushes to the potential of genetic engineering, click to read about five emerging trends that will change the world of dentistry forever.

Comments.